Partnership With Anderson Wood Products

Image from Google Street View

Anderson Wood Products (AWP), family owned and operated for over a century, manufactures component parts from American hardwoods. We source our lumber from sustainable hardwood forests as verified by the US Forest Service. Anderson operates our own kilns to control drying and moisture content. Our state-of-the-art Rough Mill utilizes vision systems and computer optimization to maximize yield while efficiently cutting at high volumes. We provide a wide array of products including handrail and associated stair parts, edge glued panels, laminated posts, stiles, rails and other machined parts. Anderson Wood is the largest American manufacturer of both hardwood dormitory bed ends and of stair railing. We are committed to meeting our customers’ needs and readily align equipment and processes to meet special requirements or create economies. Our many capabilities includes:

Finger-Jointing

Edge Gluing

Lamination

Flat Sanding

Edge Sanding

Profile Shaping & Sanding

Moulding

End Work (Coping, Mitering)

Face Boring

Edge and End Boring

Doweling

Mortising

Routing (CNC & Overhead)

Tenoning (Rotary & Conventional)

Anderson Wood has long been an industry leader in providing component parts. Now, working in conjunction with Anderson Finishing Solutions we are able to provide prefinished products that answer the full gamut of our customers’ needs all the while simplifying their purchasing.

Custom Color Formulation & Matching

Anderson Finishing Solutions can match samples provided on wood, laminate chips and most other mediums. We custom blend stain and paint to meet customers’ requirements. We can apply oil or water base stain and typically use a water-based UV topcoat. Color standards are checked within and between runs to insure consistency.

Production Capabilities

Our variety of finishing lines enables Anderson to provide one or more finishing solutions for most every customer need. Depending upon product requirements, we prime, stain and topcoat linear, panel and 3-D parts. Our equipment is configured for continuous flow to facilitate AFS handling large jobs effectively.

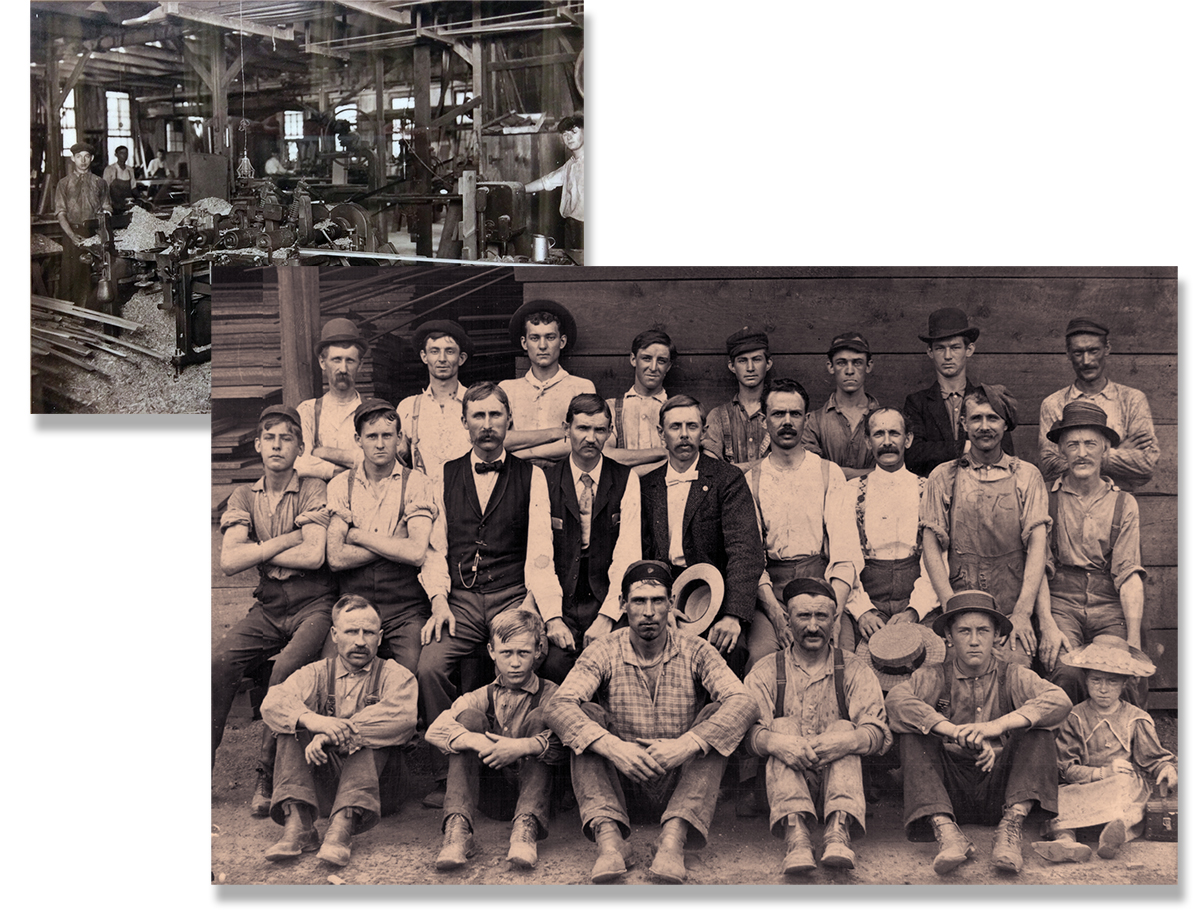

Anderson Finishing Solutions, along with its sister company Anderson Wood Products continues this Louisville tradition as a leading manufacturer of customized and/or pre-finished hardwood products. Five generations of family ownership promoting long-term partnerships with our customers, suppliers, production team, and community is the foundation of our success. We endeavor, in an ethical and credible manner, to enhance these relationships and profitability by consistently providing quality products at competitive pricing with a level of service that is unequaled in our industry.

Location

Louisville, Kentucky

Louisville, Kentucky’s largest city, has been a major location for the manufacturing industry and distribution for more than 200 years. Situated at the Falls of the Ohio, Louisville became a key port for the western frontier. Louisville’s river economy was driven by manufacturing and shipping. Louisville gained international attention for bourbon whiskey, Louisville Slugger baseball bats and the Kentucky Derby; cultural hallmarks that the city embraces.

Today Louisville continues to support a solid manufacturing base as well as being a leader in logistical and distribution services. It’s geographically centered location at the intersection of 3 Interstate Systems combined with the UPS Hub located here facilitates efficient shipping throughout the United States.